Micropiles

A micropile is a small-diameter, drilled and grouted reinforced pile typically used as a friction pile to both support structures as well as resist uplift forces.

How It's Used

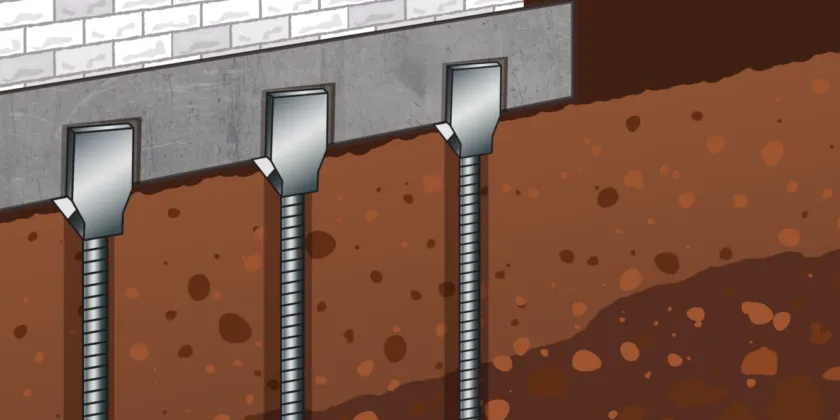

A micropile is a small-diameter (<13”), drilled and grouted reinforced pile typically used as a friction pile to both support structures as well as resist uplift forces.

Micropile Applications

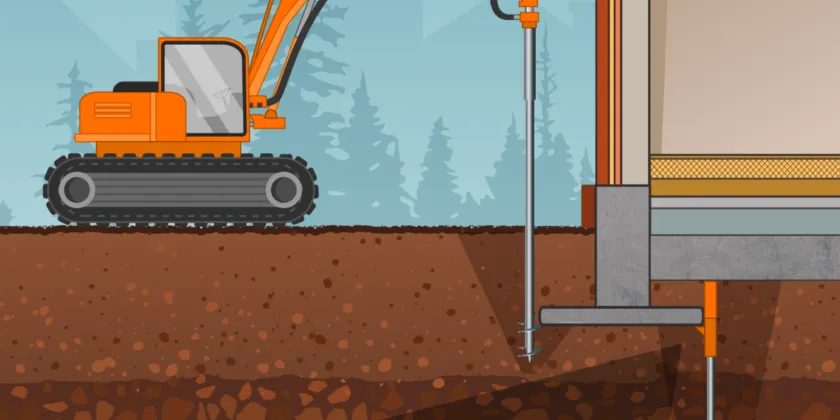

Micropiles offer a viable alternative to conventional piling techniques, particularly in sites with restricted access, areas with low headroom, challenging subsurface conditions, and environments sensitive to noise or vibration. They’re ideal for new loads in congested areas, underpinning/arresting structural settlement, seismic retrofit, slope stabilization and new construction applications. Micropiles can be installed in very limited-access conditions, and they’re well-suited for the challenging subsurface conditions found across the Rocky Mountain region.

Micropiles PROCESS

YGC provides design-build services for these small-diameter (<13”) drilled and grouted piles. A drilling technique advances the micropile casing into the substrate to design depth. After threaded steel bars are inserted, the casing is filled with high-strength grout for additional stability. YGC employs both air rotary and injection bore (hollow bar) micropile construction.

Advantages of Micropiles

Wide-ranging applications across challenging soil types and ground conditions

Excellent choice when subsurface conditions consist of cobbles, suspended shales, and other rock inclusions that would cause helical piles to refuse

Ideal for challenging and remote job sites

Minimal disturbance to nearby structures and soils

Low-vibration installation

Support large axial loads and moderate lateral loads